What is TPD in Watch Winders?

TPD stands for “Turns Per Day,” which refers to the number of rotations a watch winder completes in a 24-hour period. This measurement is crucial for automatic watch owners because it directly relates to how your timepiece would be wound through natural movement when worn on your wrist.

TPD Definition: Turns Per Day represents the number of complete rotations a watch winder makes in a 24-hour period to simulate the natural wrist movements that keep automatic watches wound.

Automatic watches contain a mechanism with a rotor that moves when the watch is in motion, winding the mainspring that powers the watch. A watch winder’s purpose is to replicate this movement when the watch isn’t being worn, keeping it running accurately and ensuring the internal lubricants remain properly distributed.

The relationship between TPD and wrist movement is straightforward: your natural daily activities typically create between 650-1200 turns for your watch, depending on your activity level. Watch winders are designed to mimic this range of movement.

To put it simply, a setting of 800 TPD means your watch will rotate approximately 33 times each hour. This consistent motion ensures your automatic watch remains wound without the need for manual intervention, just as if you were wearing it throughout the day.

Understanding TPD is the first step in properly planning your watch collection storage and maintaining your timepieces in optimal condition.

Why TPD Settings Are Critical for Automatic Watches

Selecting the correct TPD setting for your automatic watch isn’t just a matter of preference—it’s essential for the proper functioning and longevity of your timepiece. Here’s why these settings matter so much:

Key Benefits of Proper TPD Settings:

- Maintains Optimal Power Reserve: The right TPD setting ensures your watch maintains sufficient power to keep accurate time, even when not worn for several days.

- Promotes Even Lubricant Distribution: Movement keeps the special oils inside your watch properly distributed, preventing them from settling or drying out.

- Prevents Performance Issues: Incorrect settings can lead to your watch running slow, stopping completely, or experiencing inconsistent timekeeping.

- Extends Watch Lifespan: Proper winding habits help protect the intricate components inside your automatic movement from premature wear.

- Preserves Accuracy: Regular, appropriate winding helps maintain the precision of your timepiece.

When an automatic watch sits unworn and unwound, the lubricants inside begin to settle in certain areas. Over time, this can cause parts to run dry or experience increased friction, potentially leading to more significant mechanical issues and costly repairs.

Understanding proper TPD settings is particularly important when considering watch winder compatibility for your specific timepiece. Different watches have different requirements, and using incorrect settings can affect your watch’s performance over time.

For collectors with multiple timepieces, investing in quality watch winders becomes essential for maintaining each watch’s optimal condition while it’s not being worn.

How TPD Requirements Vary Across Watch Brands and Models

Not all automatic watches are created equal when it comes to winding requirements. The TPD needs of your timepiece depend on several factors specific to its design and construction:

Factors Affecting TPD Requirements:

- Mainspring Design: The size, tension, and construction of the mainspring influence how much winding is needed.

- Rotor Weight and Efficiency: Heavier rotors typically require fewer turns to achieve the same winding effect.

- Gear Ratio: The mechanical relationship between the rotor and mainspring affects winding efficiency.

- Movement Type: Different movement architectures (Swiss, Japanese, in-house) often have distinct winding needs.

These engineering differences mean that a one-size-fits-all approach simply doesn’t work for automatic watches. Each brand—and often each model within a brand—has specific requirements for optimal performance.

Typical TPD Ranges by Brand

| Watch Brand | Typical TPD Range | Common Direction |

|---|---|---|

| Rolex | 650-800 | Bidirectional |

| Omega | 650-800 | Bidirectional |

| Tag Heuer | 800-1000 | Clockwise |

| Seiko | 650-850 | Bidirectional |

| Breitling | 650-800 | Bidirectional |

| Patek Philippe | 800-1000 | Clockwise |

| Audemars Piguet | 800-950 | Bidirectional |

Entry-level automatic watches often require higher TPD settings (800-1000) due to less efficient winding mechanisms, while luxury timepieces might need fewer turns because of their more sophisticated engineering. This is why understanding your specific watch’s needs is so important.

For a more comprehensive breakdown of specific models and their requirements, our watch winder TPD settings guide provides detailed information to help you find the perfect match for your timepiece.

Finding the Correct TPD Settings for Your Watch

Determining the right TPD setting for your specific watch is crucial for proper maintenance. Here’s how to find the optimal settings for your timepiece:

How to Find Your Watch’s TPD Requirements:

Check the Watch Manual: The user manual that came with your watch often contains recommended TPD settings and rotation directions.

Contact the Manufacturer: Reach out to the watch brand’s customer service for official recommendations specific to your model.

Visit the Official Website: Many watch manufacturers now include care information in the support sections of their websites.

Consult Watch Winder Databases: Several watch winder companies maintain databases of common watch models and their TPD requirements.

Ask a Professional Watchmaker: An experienced watchmaker can provide guidance based on their knowledge of your specific movement.

Understanding Rotation Direction:

Rotation direction is just as important as TPD count. There are three common settings:

- Clockwise (CW): The winder rotates only in a clockwise direction

- Counterclockwise (CCW): The winder rotates only in a counterclockwise direction

- Bidirectional: The winder alternates between clockwise and counterclockwise rotation

Most modern watches wind efficiently with bidirectional movement, but some specific models are designed to wind primarily or exclusively in one direction. This information is typically provided alongside the TPD recommendations.

If you can’t find specific information for your watch, the general recommendation is to start with 650-800 TPD on a bidirectional setting, as this works for most automatic watches.

Properly organizing your watch collection should include keeping records of the correct TPD and rotation settings for each of your timepieces, making it easier to adjust your winders as needed.

Setting TPD and Rotation Direction on Your Watch Winder

Once you know the correct TPD and rotation direction for your watch, the next step is properly configuring your watch winder. Here’s a straightforward guide to setting up most common winder models:

Steps to Set Your Watch Winder:

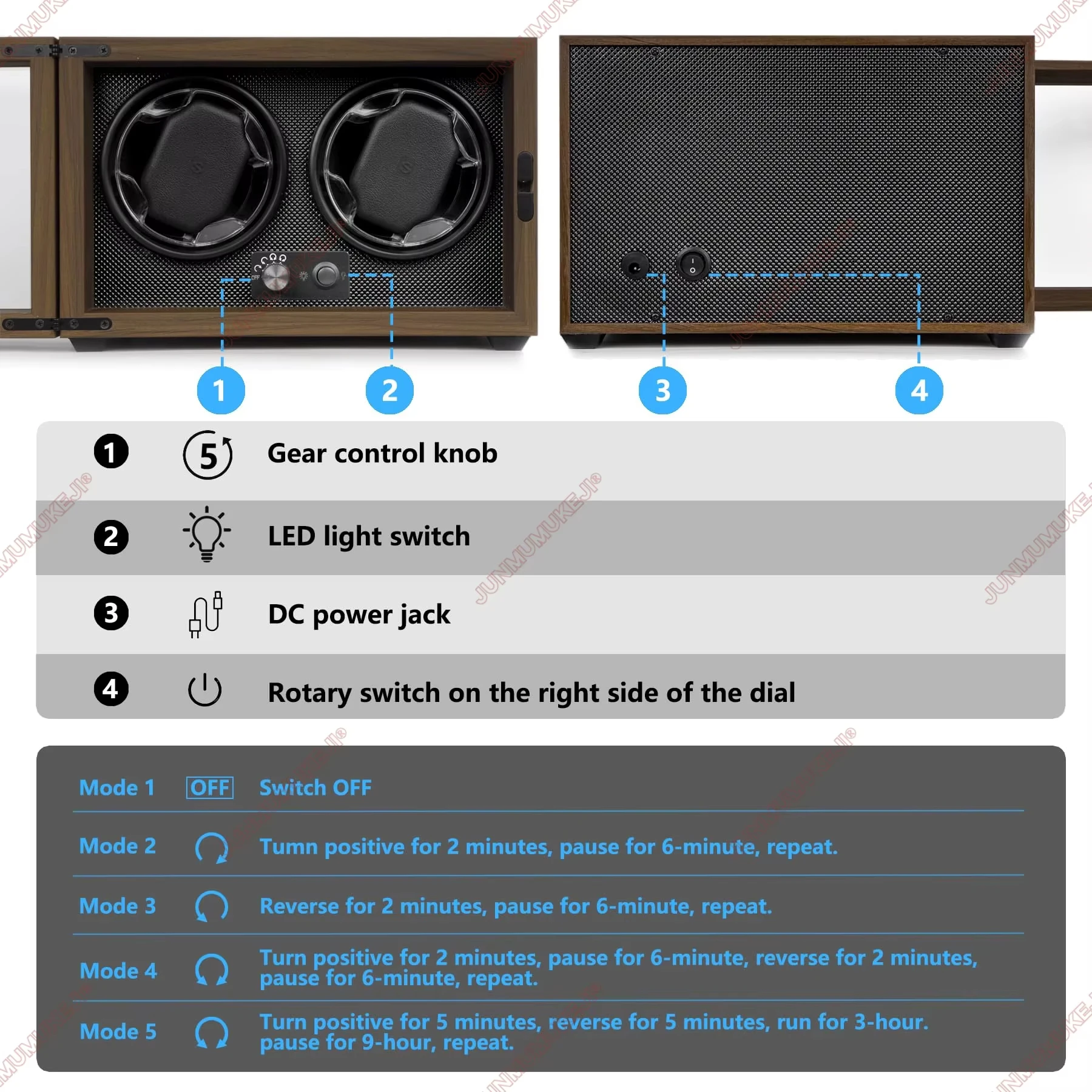

Locate the Control Panel: Depending on your winder model, this may be on the back, side, or front of the unit.

Select TPD Setting: Most winders offer preset TPD options (e.g., 650, 750, 850, 1000). Choose the setting closest to your watch’s requirement.

Choose Rotation Direction: Select clockwise, counterclockwise, or bidirectional based on your watch’s needs.

Wind Your Watch Manually First: Before placing your watch in the winder, give it 20-30 manual winds to ensure it has an initial power reserve.

Position the Watch Correctly: Place your watch securely in the winder cup, ensuring it sits straight and secure.

Start the Winder: Once settings are configured and the watch is properly positioned, start the winder’s program.

Check After 24 Hours: Verify that your watch is keeping proper time after a full day in the winder. If it’s losing time, you may need to increase the TPD setting.

For digital winders with LCD screens, navigation is typically done using arrow buttons to cycle through options. For analog winders with dials or switches, you’ll need to align the indicators with your desired settings.

For more detailed instructions specific to different winder types and models, our guide on how to program watch winders provides comprehensive step-by-step setup information.

The Impact of Incorrect TPD Settings

Using improper TPD settings can affect your automatic watch in several ways. Understanding these potential issues helps ensure your timepiece remains in optimal condition.

Too Low TPD:

- Watch Stops Running: Insufficient winding leads to power reserve depletion.

- Decreased Accuracy: Before stopping completely, the watch may lose time or run irregularly.

- Inconsistent Performance: The watch might run for a while, then stop unexpectedly.

- Lubricant Settling: Over time, oils and lubricants may collect in certain areas, leading to increased friction in the movement.

Too High TPD:

- The Overwinding Myth: Most modern automatic watches have a slipping clutch mechanism that prevents true overwinding damage.

- Unnecessary Wear: While damage is unlikely, excessive movement may cause slightly faster wear on certain components over many years.

- Energy Waste: Higher than necessary TPD settings waste electricity without providing benefits.

- Potentially Noisy Operation: Some winders become louder when operating at higher TPD settings.

The good news is that modern automatic watches are designed with protective mechanisms that make them quite resistant to damage from excessive winding. The mainspring is engineered with a slipping clutch that prevents over-tensioning once fully wound.

However, underwinding presents more immediate concerns, as it directly affects your watch’s timekeeping ability and can lead to the timepiece stopping completely. When this happens repeatedly over long periods, it may affect the watch’s overall performance.

Signs that your TPD settings need adjustment include:

– Watch stopping despite being in the winder

– Significant time loss (more than a few minutes per day)

– The watch runs for short periods then stops

Our collection of automatic watch winders features models with adjustable TPD settings to accommodate different watch requirements and help prevent these issues.

Troubleshooting TPD Issues and Winding Problems

Even with correct settings, you may occasionally encounter winding issues. Here’s how to identify and resolve common problems:

Common Issues and Solutions:

Q: My watch stops running even though it’s in the winder with the correct TPD.

A: First, ensure your watch is functioning properly by manually winding it and checking if it runs for at least 24 hours. If it does, the issue is likely with the winder. Check that the watch is securely positioned and that the winder is actually rotating as programmed.

Q: My watch winder is running, but my watch isn’t staying wound.

A: Try increasing the TPD setting by 50-100 turns. Some watches need more movement than the manufacturer’s standard recommendation, particularly as they age. Also, ensure the rotation direction setting is appropriate for your specific watch.

Q: How do I find the right TPD when documentation is unavailable?

A: Use this experimental approach:

1. Start at 650 TPD on bidirectional setting

2. Check if your watch maintains time over 24-48 hours

3. If it stops or loses significant time, increase by 100 TPD

4. Repeat until you find the lowest setting that keeps your watch running accurately

Q: My watch loses time despite being in a winder.

A: This could indicate that either the TPD is too low or your watch may need servicing. If increasing the TPD doesn’t solve the issue, consider having your watch examined by a professional.

Q: The watch works fine when worn but not in the winder.

A: Your activity level may provide more motion than your current winder setting. Try a higher TPD setting or ensure the winder is operating continuously rather than in intervals.

For persistent issues that you can’t resolve through TPD adjustments, consider consulting our guide to troubleshooting common watch winder problems, which covers mechanical issues that might affect winding performance.

Frequently Asked Questions About TPD and Watch Winders

Is there a universal TPD setting that works for most watches?

While each watch has specific requirements, a setting of 650-800 TPD on bidirectional rotation works for approximately 80% of automatic watches. This can be a good starting point if you’re unsure about your watch’s exact needs.

Can I damage my watch with incorrect TPD settings?

Modern automatic watches have built-in protection against overwinding damage. However, consistently underwinding your watch by using too low a TPD setting can cause it to stop running and potentially affect timekeeping accuracy over time.

Do all automatic watches need the same rotation direction?

No. While many modern watches wind efficiently with bidirectional rotation, some models are designed to wind primarily or exclusively in one direction (clockwise or counterclockwise). Check your watch’s documentation for specific recommendations.

How long does it take to fully wind a watch in a winder?

A completely unwound watch typically requires 12-24 hours in a properly configured winder to reach full power reserve. This is why manually winding your watch before placing it in the winder is recommended.

Should I run my watch winder continuously or intermittently?

For watches worn occasionally (1-3 times per week), continuous operation is typically best. For watches worn more frequently, intermittent winding (8-12 hours per day) is usually sufficient and can extend the winder’s lifespan.

Do I need to manually wind my watch before placing it in a winder?

Yes, it’s generally recommended to give your watch 20-30 manual winds before placing it in a winder. This ensures there’s enough initial power reserve for the automatic winding mechanism to function effectively.

For collectors looking to properly store their timepieces when not in use, exploring different watch storage ideas can help preserve your collection while keeping pieces easily accessible.

Advanced Considerations for Multiple Watch Collections

Managing a diverse collection of automatic watches presents unique challenges, particularly when each timepiece has different TPD requirements. Here are strategies to effectively maintain multiple watches:

Multi-Watch Collection Management:

Document Each Watch’s Requirements: Create a simple spreadsheet or notebook listing each watch’s optimal TPD setting, rotation direction, and other specific needs.

Invest in Programmable Multi-Watch Winders: Higher-end winders with multiple independently programmable winding modules allow you to set different TPD values for each watch position.

Create a Rotation Schedule: If you have more watches than winder positions, establish a schedule to rotate different watches through your winder based on when you plan to wear them.

Group Similar Watches: If using a winder with uniform settings, group watches with similar TPD requirements together.

Prioritize Complicated Watches: Timepieces with complications like perpetual calendars or moon phases should take priority in your winder to avoid the hassle of resetting complex functions.

For collectors with rarely worn pieces, consider a partial rotation system where watches are cycled through the winder for a week each month, providing enough motion to keep lubricants distributed without unnecessarily running the winder continuously.

Men's Watch Organizer, Watch Display Case, Watch Organizer

Price range: $112.68 through $169.45 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Watch Winder, Luxury Watch Winder, Single Watch Box

$307.39 Select options This product has multiple variants. The options may be chosen on the product page4 Watch Winder, 6 Watch Box, Automatic Watch Winder

$512.31 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Watch Winder, Single Watch Winder, Wooden Watch Holder

$201.76 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Watch Winder, Leather Watch Travel Case, Single Watch Winder

$146.30 Select options This product has multiple variants. The options may be chosen on the product pageAutomatic Watch Winder, Double Watch Winder, Leather Watch Boxes

$147.60 Select options This product has multiple variants. The options may be chosen on the product page

Our selection of luxury watch winders offers multiple independently programmable modules ideal for serious collectors with diverse watch collections requiring different TPD settings.

TPD and Watch Winder Quality: What to Look For

The precision and consistency of TPD delivery varies significantly between watch winders of different quality levels. Here’s what to consider when evaluating watch winders with TPD capabilities in mind:

Quality Indicators for TPD Performance:

Programmable TPD Settings: Better winders offer multiple precise TPD options rather than just “high/medium/low” settings.

Motor Quality: Premium motors provide more consistent rotation speed, delivering more accurate TPD counts over time.

Rotation Smoothness: High-quality winders start and stop gradually, better simulating natural wrist movement.

Directional Control: The ability to program specific rotation patterns (CW, CCW, or bidirectional) with adjustable timing.

Noise Level: Quality winders operate quietly, important for bedroom placement.

Power Backup or Memory: Better winders remember your settings during power outages or when unplugged.

Testing and Calibration: Premium brands regularly test and calibrate their winders to ensure accurate TPD delivery.

The construction quality of the winder directly impacts TPD consistency. Budget winders may claim certain TPD settings but often lack the precision engineering to deliver them consistently. This can result in under-winding or irregular rotation patterns that don’t properly maintain your watches.

For displaying your collection when not in the winder, consider our range of watch display cases designed to complement your winding solution while showcasing your timepieces.

At Daily Accents, we understand that proper watch maintenance goes beyond basic storage. Our selection of watch winders and display solutions is designed to meet the specific needs of discerning collectors who recognize the importance of proper TPD settings in preserving the value and performance of their fine timepieces.